Technical Information

Steel & Its different sub groups & grades

There are four types steel –

Carbon Steel –

Carbon steels only contain trace amounts of elements besides carbon and iron. Carbon Steel has three main subgroups depending on how much carbon is in the metal:

Low Carbon Steels/Mild Steels (up to 0.3% carbon),

Medium Carbon Steels (0.3–0.6% carbon), and

High Carbon Steels (more than 0.6% carbon).

Stainless Steel –

Stainless steels contain 10-30% chromium as their alloying element, as well as other elements such as nickel, silicon, manganese and carbon. It’s is grouped into four subcategories that each serve a different purpose.

Ferritic SS (200 Series): These are less-expensive steels with low amounts of carbon and nickel. Automotive applications are common final destinations for ferritic alloys because of their chromium-induced strength and sheen.

Austenitic SS (300 Series): Austenitic alloys have higher chromium and nickel contents, improving their resistance to corrosion and causing them to become non-magnetic. They’re present in commercial kitchen appliances and are popular because they’re durable and easy to clean.

Martensitic SS (400 Series): Toughness is a hallmark of martensitic alloys, but they’re prone to corrosion. They’re formed by a rapid-cooling process that makes them ideal for heat treatment and are found in medical instruments, cutlery and pliers.

Duplex SS: A combination of austenitic and ferritic alloys results in a Duplex Stainless Steel that inherits the properties of both while doubling strength. They’re also ductile and corrosion-resistant due to their fairly high chromium content.

Other SS: Heat resisting Chromium Alloys (500 series) & Austenitic Chromium & Molybdenum Alloys (900 Series)

Alloy Steel –

The Alloy type is iron fused with one of several other elements, each contributing its own unique attributes to the final product. Any steel which contains more than 1.65 % manganese, 0.60 % silicon and 0.60 % copper or a definite minimum amount of any other element, is termed an ‘Alloy’ steel.

Alloy steels are created by adding additional alloying elements like nickel, copper, chromium, manganese, molybdenum, silicon, vanadium etc., (most common) and/or aluminium, cobalt, copper, titanium, zinc, lead (less common) etc.,

Alloy steels are normally of three types. They are Micro-Alloyed Steels (high strength low alloy), Low Alloy Steels (from 2.07% up to 10%Cr) and High Alloyed Steels (above 10%Cr).

Incorporating these alloying elements enhances the steel’s strength, hardness, toughness, corrosion resistance, wear resistance, hardenability, machinability, heat resistance, fire resistance can be processed with heat treatment to achieve some of these improved properties.

Tool Steels – (currently not in our scope of supply, just for Information)

Tool Steels, as you can probably guess by the name, excel in cutting and drilling equipment. The secret is the tungsten, molybdenum, cobalt, and vanadium that increases their heat resistance and overall durability. And since they retain their shape under heavy usage, they’re the go-to material for most hand tools.

| Nominal Pipe Dia | Flange Dia | Dia – Bolt Circle | No Of Bolt Holes | No of Holes | Thk. Of Flange | Hub Dia. | Length Through Hub | Bore Dia | RF Dia | Depth Of Socket | Pipe Dia | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S/O & S/W | W/N | L/J | S/O & S/W | L/J | ||||||||||

| O | A | D | C | E | Y | Y | Y | B | B | R | F | X | ||

| DIMENSIONS OF CLASS 150 FLANGES AS PER ASME / ANSI B 16.5 | ||||||||||||||

| 15.0 | 89.0 | 60.5 | 15.9 | 4.0 | 11.7 | 30.0 | 16 | 48.0 | 16.0 | 22.2 | 22.9 | 34.9 | 9.5 | 21.3 |

| 20.0 | 99.0 | 69.8 | 15.9 | 4.0 | 13.2 | 38.0 | 16 | 53.0 | 16.0 | 27.7 | 28.2 | 42.9 | 11.1 | 26.7 |

| 25.0 | 108.0 | 79.2 | 15.9 | 4.0 | 14.7 | 49.0 | 18 | 56.0 | 17.0 | 34.5 | 34.9 | 50.8 | 12.7 | 33.4 |

| 32.0 | 117.0 | 88.9 | 15.9 | 4.0 | 16.2 | 59.0 | 21 | 58.0 | 21.0 | 43.2 | 43.7 | 63.5 | 14.3 | 42.2 |

| 40.0 | 127.0 | 98.4 | 15.9 | 4.0 | 17.9 | 65.0 | 23 | 62.0 | 22.0 | 49.5 | 50.0 | 73.0 | 15.9 | 48.3 |

| 50.0 | 152.0 | 120.6 | 19.1 | 4.0 | 19.5 | 78.0 | 26 | 64.0 | 25.0 | 61.9 | 62.5 | 92.1 | 17.5 | 60.3 |

| 65.0 | 178.0 | 139.7 | 19.1 | 4.0 | 22.6 | 90.0 | 29 | 70.0 | 29.0 | 74.6 | 75.4 | 104.8 | 19.0 | 73.0 |

| 80.0 | 190.0 | 152.4 | 19.1 | 4.0 | 24.4 | 108.0 | 31 | 70.0 | 30.0 | 90.7 | 91.4 | 127.0 | 20.6 | 88.9 |

| 100.0 | 229.0 | 190.5 | 19.1 | 8.0 | 24.4 | 135.0 | 34 | 77.0 | 33.0 | 116.8 | 116.8 | 157.2 | – | 114.3 |

| 125.0 | 254.0 | 215.9 | 22.2 | 8.0 | 24.4 | 164.0 | 37 | 89.0 | 36.0 | 143.8 | 144.5 | 185.7 | – | 141.3 |

| 150.0 | 279.0 | 241.3 | 22.2 | 8.0 | 25.9 | 192.0 | 40 | 89.0 | 40.0 | 170.7 | 171.4 | 215.9 | – | 168.3 |

| 200.0 | 343.0 | 298.4 | 22.2 | 8.0 | 28.9 | 246.0 | 45 | 102.0 | 44.0 | 221.5 | 222.2 | 269.9 | – | 219.1 |

| 250.0 | 406.0 | 362.0 | 25.4 | 12.0 | 30.4 | 305.0 | 50 | 102.0 | 49.0 | 276.2 | 277.4 | 323.8 | – | 273.0 |

| 300.0 | 483.0 | 431.8 | 25.4 | 12.0 | 32.2 | 365.0 | 56 | 115.0 | 56.0 | 327.0 | 328.2 | 381.0 | – | 323.8 |

| 350.0 | 533.0 | 476.2 | 28.6 | 12.0 | 35.3 | 400.0 | 58 | 127.0 | 79.0 | 359.2 | 360.2 | 412.7 | – | 355.6 |

| 400.0 | 597.0 | 539.8 | 28.6 | 16.0 | 37.1 | 457.0 | 64 | 127.0 | 87.0 | 410.5 | 411.2 | 469.9 | – | 406.4 |

| 450.0 | 635.0 | 577.8 | 31.8 | 16.0 | 40.1 | 505.0 | 69 | 140.0 | 97.0 | 461.8 | 462.3 | 533.4 | – | 457.2 |

| 500.0 | 698.0 | 635.0 | 31.8 | 20.0 | 43.1 | 559.0 | 73 | 145.0 | 103.0 | 513.1 | 514.3 | 584.2 | – | 508.0 |

| 600.0 | 813.0 | 749.3 | 34.9 | 20.0 | 48.0 | 663.0 | 83 | 153.0 | 111.0 | 616.0 | 616.0 | 692.1 | – | 610.0 |

| DIMENSIONS OF CLASS 300 FLANGES AS PER ASME / ANSI B 16.5 | ||||||||||||||

| 15.0 | 95.0 | 66.5 | 15.9 | 4.0 | 14.7 | 38.0 | 23 | 53.0 | 22.0 | 22.2 | 22.9 | 34.9 | 9.5 | 21.3 |

| 20.0 | 117.0 | 82.6 | 19.1 | 4.0 | 16.2 | 48.0 | 26 | 58.0 | 25.0 | 27.2 | 28.2 | 42.9 | 11.1 | 26.7 |

| 25.0 | 124.0 | 88.9 | 19.1 | 4.0 | 17.7 | 54.0 | 27 | 62.0 | 27.0 | 34.5 | 34.9 | 50.8 | 12.7 | 33.4 |

| 32.0 | 133.0 | 98.6 | 19.1 | 4.0 | 19.5 | 64.0 | 27 | 66.0 | 27.0 | 43.2 | 43.7 | 63.5 | 14.3 | 42.2 |

| 40.0 | 155.0 | 114.3 | 22.2 | 4.0 | 21 | 70.0 | 31 | 69.0 | 30.0 | 49.5 | 50.0 | 73.0 | 15.9 | 48.3 |

| 50.0 | 165.0 | 127.0 | 22.2 | 8.0 | 22.6 | 84.0 | 34 | 70.0 | 33.0 | 61.9 | 62.5 | 92.1 | 17.5 | 60.3 |

| 65.0 | 190.0 | 149.4 | 22.2 | 8.0 | 25.9 | 100.0 | 39 | 77.0 | 38.0 | 74.6 | 75.4 | 104.8 | 19.0 | 73.0 |

| 80.0 | 210.0 | 168.1 | 22.2 | 8.0 | 28.9 | 117.0 | 43 | 80.0 | 43.0 | 90.7 | 91.4 | 127.0 | 20.6 | 88.9 |

| 100.0 | 254.0 | 200.2 | 22.2 | 8.0 | 32.2 | 146.0 | 48 | 86.0 | 48.0 | 116.8 | 116.8 | 157.2 | – | 114.3 |

| 125.0 | 279.0 | 235.0 | 22.2 | 8.0 | 35.3 | 178.0 | 51 | 99.0 | 51.0 | 143.8 | 144.5 | 185.7 | – | 141.3 |

| 150.0 | 318.0 | 269.7 | 22.2 | 12.0 | 37.1 | 206.0 | 53 | 99.0 | 52.0 | 170.7 | 171.4 | 215.9 | – | 168.3 |

| 200.0 | 381.0 | 330.2 | 25.4 | 12.0 | 41.6 | 260.0 | 62 | 112.0 | 62.0 | 221.5 | 222.2 | 269.9 | – | 219.1 |

| 250.0 | 444.0 | 387.4 | 28.6 | 16.0 | 48 | 321.0 | 67 | 118.0 | 95.0 | 276.2 | 277.4 | 323.8 | – | 273.0 |

| 300.0 | 521.0 | 450.8 | 31.8 | 16.0 | 51.3 | 375.0 | 73 | 131.0 | 102.0 | 327.0 | 328.2 | 381.0 | – | 323.8 |

| 350.0 | 584.0 | 514.4 | 31.8 | 20.0 | 54.3 | 425.0 | 77 | 143.0 | 111.0 | 359.2 | 360.2 | 412.8 | – | 355.6 |

| 400.0 | 648.0 | 571.5 | 34.9 | 20.0 | 57.6 | 483.0 | 83 | 146.0 | 121.0 | 410.5 | 411.2 | 469.9 | – | 406.4 |

| 450.0 | 711.0 | 628.6 | 34.9 | 24.0 | 60.7 | 533.0 | 89 | 159.0 | 130.0 | 461.8 | 462.3 | 533.4 | – | 457.0 |

| 500.0 | 775.0 | 685.8 | 34.9 | 24.0 | 64 | 587.0 | 96 | 162.0 | 140.0 | 513.1 | 514.3 | 584.2 | – | 508.0 |

| 600.0 | 914.0 | 812.8 | 41.3 | 24.0 | 70.3 | 702.0 | 107 | 169.0 | 153.0 | 616.0 | 616.0 | 692.2 | – | 610.0 |

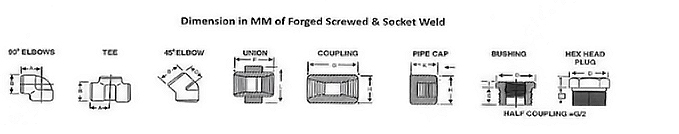

| SOCKETWELD FITTINGS TO ASME / ANSI B 16.11 – 3000 / 6000 LBS | |||||||||||||||||||

| Nominal Pipe Size | 3000 LBS | Common Factor | 6000 LBS | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | mm | A max | B max | K | M | N | C min. | D min. | J | L | O min. | O max. | P | Q | A max | B max | K | M | N |

| 1/8″ | 10.3 | 22 | 18.5 | 26 | 17.3 | 32 | 10.7 | 10 | 16 | 40 | 5 | 8 | 17.5 | 10 | 22 | 22 | 25 | 20 | 46 |

| 1/4″ | 13.7 | 22 | 22.0 | 26 | 21.2 | 32 | 14.1 | 10 | 18 | 43 | 5 | 8 | 17.5 | 10 | 27 | 25 | 25 | 24 | 51 |

| 3/8″ | 17.2 | 25 | 25.0 | 26 | 25.4 | 36 | 17.6 | 10 | 19 | 48 | 3 | 9 | 19.0 | 10 | 27 | 28 | 26 | 28 | 60 |

| 1/2″ | 21.3 | 27 | 32.0 | 30 | 31.0 | 41 | 21.7 | 10 | 21 | 51 | 6 | 13 | 22.0 | 10 | 31 | 34 | 31 | 34 | 72 |

| 3/4″ | 26.7 | 34 | 38.0 | 36 | 37.0 | 50 | 27.0 | 13 | 24 | 57 | 6 | 13 | 25.0 | 13 | 37 | 42 | 35 | 41 | 80 |

| 1″ | 33.4 | 37 | 46.0 | 40 | 45.2 | 60 | 33.8 | 13 | 25 | 64 | 9 | 17 | 27.0 | 13 | 42 | 50 | 40 | 50 | 94 |

| 1.1/4″ | 42.2 | 42 | 56.0 | 40 | 55.0 | 70 | 42.6 | 13 | 29 | 70 | 9 | 17 | 30.0 | 13 | 47 | 59 | 41 | 58 | 100 |

| 1.1/2″ | 48.3 | 47 | 62.0 | 40 | 61.4 | 78 | 48.7 | 13 | 30 | 79 | 9 | 17 | 32.0 | 13 | 53 | 67 | 43 | 66 | 122 |

| 2″ | 60.3 | 56 | 75.0 | 52 | 75.0 | 95 | 61.2 | 13 | 37 | 89 | 15 | 23 | 38.0 | 13 | 59 | 84 | 55 | 83 | – |

| 2.1/2″ | 73.0 | 60 | 92.0 | 52 | 91.3 | 125 | 73.8 | 16 | 48 | 114 | 14 | 24 | 38.0 | 16 | – | 102 | 56 | – | – |

| 3″ | 89.0 | 76 | 110.0 | 52 | 108.8 | 140 | 89.8 | 16 | 51 | 127 | 14 | 24 | 44.0 | 16 | – | 121 | 58 | – | – |

| 4″ | 114.5 | 88 | 137.0 | 58 | 136.9 | – | 115.5 | 19 | – | 150 | 14 | 24 | 48.0 | 19 | – | 152 | 64 | – | – |

| FORGED THREADED FITTINGS TO ASME / ANSI B 16.11 – 3000 / 6000 LBS, THREADING ASA B 2.1 | |||||||||||||||||||

| Nominal Pipe Size | 3000 LBS | Common Factor | 6000 LBS | ||||||||||||||||

| Inch | mm | A | B | C | G | H | K | D | E | F | I | J | L | A | B | C | G | H | K |

| 1/8″ | 10.3 | 21 | 22 | 17 | 32 | 16 | 19 | 11 | 10 | 40 | – | 6 | – | 25 | 25 | 19 | 32 | 22 | – |

| 1/4″ | 13.7 | 25 | 25 | 19 | 35 | 19 | 25 | 16 | 11 | 43 | 3 | 6 | 32 | 29 | 33 | 22 | 35 | 25 | 27 |

| 3/8″ | 17.2 | 29 | 33 | 22 | 38 | 22 | 25 | 17.5 | 13 | 48 | 4 | 8 | 38 | 33 | 38 | 25 | 38 | 32 | 27 |

| 1/2″ | 21.3 | 33 | 38 | 25 | 48 | 29 | 32 | 22 | 15 | 51 | 5 | 8 | 46 | 38 | 46 | 29 | 48 | 38 | 33 |

| 3/4″ | 26.7 | 38 | 46 | 29 | 51 | 35 | 37 | 27 | 16 | 57 | 6 | 10 | 51 | 44 | 56 | 33 | 51 | 44 | 38 |

| 1″ | 33.4 | 44 | 56 | 33 | 60 | 44 | 41 | 35 | 19 | 64 | 6 | 10 | 60 | 51 | 62 | 35 | 60 | 57 | 43 |

| 1.1/4″ | 42.2 | 51 | 62 | 35 | 67 | 57 | 44 | 44.5 | 21 | 70 | 7 | 14 | 72 | 60 | 75 | 43 | 67 | 64 | 46 |

| 1.1/2″ | 48.3 | 60 | 75 | 43 | 79 | 64 | 44 | 51 | 21 | 79 | 8 | 16 | 80 | 64 | 84 | 44 | 79 | 76 | 48 |

| 2″ | 60.3 | 64 | 84 | 45 | 86 | 76 | 48 | 63.5 | 22 | 88 | 9 | 17 | 94 | 83 | 102 | 52 | 86 | 92 | 51 |

| 2.1/2″ | 73.02 | 83 | 102 | 52 | 92 | 92 | 60 | 76 | 27 | 118 | 10 | 21 | 122 | 95 | 121 | 64 | 92 | 108 | 64 |

| 3″ | 89 | 95 | 121 | 64 | 108 | 108 | 65 | 89 | 29 | 121 | 10 | 25 | 140 | 106 | 146 | 79 | 108 | 127 | 68 |

| 4″ | 114.5 | 114 | 152 | 79 | 121 | 140 | 68 | 117.5 | 32 | 150 | 13 | 25 | 180 | 114 | 152 | 79 | 121 | 159 | 75 |

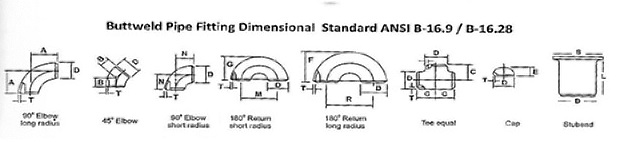

| Buttweld Pipe Fittings Dimensional Standard ASME/ANSI B-16.9 / B-16.28 | ||||||||||||||

| Nominal Pipe Size | Outside Diameter | Center To Face | Back To Face | Center To Center | Length ‘L’ | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch. | mm | D | A | B | C | N | E | F | G | R | M | S | L | L |

| 1/2 | 15.0 | 21.3 | 38.0 | 16.0 | 25.0 | – | 25.0 | 43.0 | – | 76.0 | – | 35.0 | 50.8 | 76.2 |

| 3/4 | 20.0 | 26.7 | 29.0 | 11.0 | 29.0 | – | 25.0 | 43.0 | – | 57.0 | – | 43.0 | 50.8 | 76.2 |

| 1 | 25.0 | 33.4 | 38.0 | 22.0 | 38.0 | 25.0 | 38.0 | 56.0 | 41.0 | 76.0 | 51.0 | 51.0 | 50.8 | 101.6 |

| 1.1/4 | 32.0 | 42.2 | 48.0 | 25.0 | 48.0 | 32.0 | 38.0 | 70.0 | 52.0 | 95.0 | 64.0 | 64.0 | 50.8 | 101.6 |

| 1.1/2 | 40.0 | 48.3 | 57.0 | 29.0 | 57.0 | 38.0 | 38.0 | 83.0 | 62.0 | 114.0 | 76.0 | 73.0 | 50.8 | 101.6 |

| 2 | 50.0 | 60.3 | 76.0 | 35.0 | 64.0 | 51.0 | 38.0 | 106.0 | 81.0 | 152.0 | 102.0 | 93.0 | 63.5 | 152.4 |

| 2.21/2 | 65.0 | 73.0 | 95.3 | 44.0 | 76.0 | 64.0 | 38.0 | 132.0 | 100.0 | 191.0 | 127.0 | 105.0 | 63.5 | 152.4 |

| 3 | 80.0 | 88.9 | 114.3 | 51.0 | 86.0 | 76.0 | 51.0 | 159.0 | 121.0 | 229.0 | 152.0 | 127.0 | 63.5 | 152.4 |

| 3.1/2 | 90.0 | 101.6 | 133.4 | 57.0 | 95.0 | 89.0 | 64.0 | 184.0 | 140.0 | 267.0 | 178.0 | 140.0 | 76.2 | 152.4 |

| 4 | 100.0 | 114.3 | 152.0 | 63.0 | 105.0 | 102.0 | 64.0 | 210.0 | 159.0 | 305.0 | 203.0 | 157.0 | 76.2 | 152.4 |

| 5 | 125.0 | 141.3 | 190.0 | 79.0 | 123.0 | 127.0 | 76.0 | 262.0 | 197.0 | 381.0 | 254.0 | 186.0 | 76.2 | 203.2 |

| 6 | 150.0 | 168.3 | 229.0 | 95.0 | 143.0 | 152.0 | 89.0 | 313.0 | 237.0 | 457.0 | 305.0 | 216.0 | 88.9 | 203.2 |

| 8 | 200.0 | 219.1 | 304.0 | 127.0 | 178.0 | 203.0 | 102.0 | 414.0 | 313.0 | 610.0 | 406.0 | 270.0 | 101.6 | 203.2 |

| 10 | 250.0 | 273.1 | 381.0 | 159.0 | 216.0 | 254.0 | 127.0 | 515.0 | 391.0 | 762.0 | 508.0 | 324.0 | 127.0 | 254.0 |

| 12 | 300.0 | 323.9 | 457.0 | 190.0 | 254.0 | 303.0 | 152.0 | 619.0 | 467.0 | 914.0 | 310.0 | 381.0 | 152.4 | 254.0 |

| 14 | 350.0 | 355.6 | 533.0 | 222.0 | 279.0 | 356.0 | 165.0 | 711.0 | 533.0 | 1067.0 | 711.0 | 413.0 | 152.4 | 305.0 |

| 16 | 400.0 | 406.4 | 610.0 | 254.0 | 305.0 | 406.0 | 178.0 | 813.0 | 610.0 | 1219.0 | 813.0 | 470.0 | 152.4 | 305.0 |

| 18 | 450.0 | 457.2 | 686.0 | 286.0 | 343.0 | 457.0 | 203.0 | 914.0 | 686.0 | 1372.0 | 914.0 | 533.0 | 152.4 | 305.0 |

| 20 | 500.0 | 508.0 | 762.0 | 318.0 | 381.0 | 508.0 | 229.0 | 1016.0 | 762.0 | 1524.0 | 1016.0 | 584.0 | 152.4 | 305.0 |

| 22 | 550.0 | 559.0 | 838.0 | 343.0 | 419.0 | 559.0 | 254.0 | 1118.0 | 838.0 | 1676.0 | 1118.0 | 614.0 | 152.4 | 305.0 |

| 24 | 600.0 | 610.0 | 914.0 | 381.0 | 432.0 | 610.0 | 267.0 | 1219.0 | 914.0 | 1829.0 | 1219.0 | 692.0 | 152.4 | 305.0 |

| 26 | 650.0 | 660.0 | 991.0 | 406.0 | 495.0 | 660.0 | 267.0 |

|

||||||

| 30 | 750.0 | 762.0 | 1143.0 | 470.0 | 589.0 | 762.0 | 267.0 | |||||||

| 32 | 800.0 | 813.0 | 1219.0 | 502.0 | 597.0 | 813.0 | 267.0 | |||||||

| 34 | 850.0 | 864.0 | 1295.0 | 533.0 | 635.0 | 864.0 | 267.0 | |||||||

| 36 | 900.0 | 914.0 | 1372.0 | 565.0 | 673.0 | 914.0 | 267.0 | |||||||